One of the most commonly used metals for metal stamping is steel. However, not all steel alloys are alike, and each type has its own unique qualities. Selecting a steel alloy for a metal stamping project depends on the application’s specific requirements. The most common types of steel used for metal stamping include carbon steel, alloy steel, and stainless steel.

One of the most commonly used metals for metal stamping is steel. However, not all steel alloys are alike, and each type has its own unique qualities. Selecting a steel alloy for a metal stamping project depends on the application’s specific requirements. The most common types of steel used for metal stamping include carbon steel, alloy steel, and stainless steel.

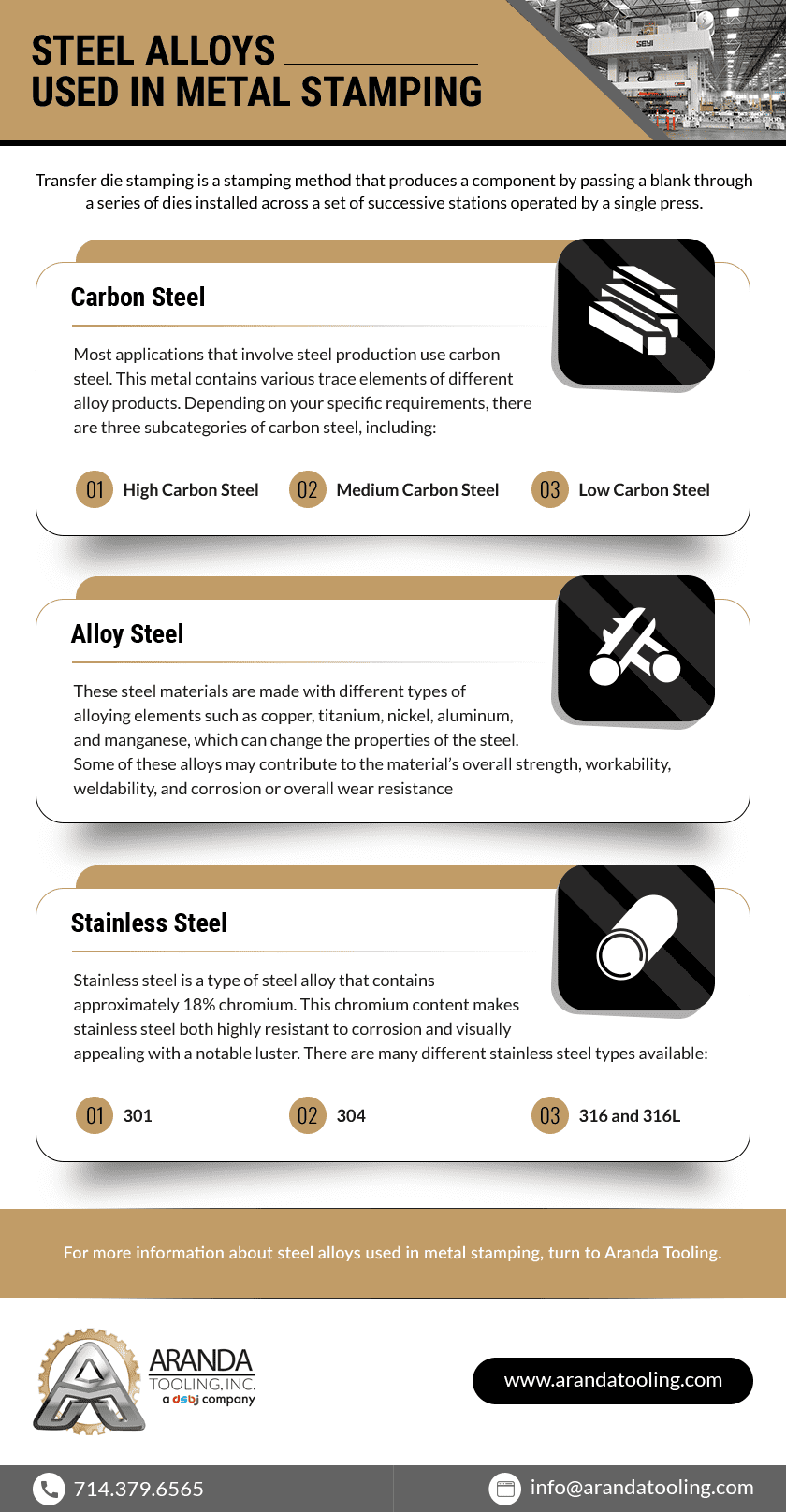

Types of Steel for Metal Stamping

When choosing the right steel for a metal stamping project, consider whether you want carbon, alloy, or stainless steel. The following offers a breakdown of their differences to help you determine which is suitable for your application.

Carbon Steel

Most applications that involve steel production use carbon steel. This metal contains various trace elements of different alloy products. Depending on your specific requirements, there are three subcategories of carbon steel, including:

- High Carbon Steel. This carbon steel features carbon content comprising 0.60% to 1.4% of the total weight. While the high carbon content makes it the most durable of the carbon steel alloys, it’s also the least workable.

- Medium Carbon Steel. Carbon contents for medium carbon steel are between 0.25% and 0.60% of the steel’s mass. This type of carbon steel is normally combined with other alloys such as chromium and molybdenum to increase its strength and resistance to wear.

- Low Carbon Steel. Low carbon steels feature carbon contents of 0.03% to 0.08%. The low carbon content makes them highly resistant to corrosion, and they are far more workable than high carbon steel.

Alloy Steel

These steel materials are made with different types of alloying elements such as copper, titanium, nickel, aluminum, and manganese, which can change the properties of the steel. Some of these alloys may contribute to the metal stamping material’s overall strength, workability, weldability, and corrosion or overall wear resistance. Alloy steels are commonly used for a variety of parts, including transformers, electric motors, pipelines, and automotive parts.

Stainless Steel

Stainless steel is a type of steel alloy that contains approximately 18% chromium. This chromium content makes stainless steel both highly resistant to corrosion and visually appealing with a notable luster. Stainless steel is often more costly to use than other alloys, but the increased durability and corrosion resistance make it worth the higher price. Depending on your steel stamping needs, there are a few different stainless steel types available:

- 301. This stainless steel features high tensile strength along with corrosion and rust resistance. It’s available in three subcategories including hard, half hard, and full hard.

- 304. For products that need moderate tensile strength in addition to corrosion and rust resistance, 304 grade stainless steel is ideal. It’s frequently used for stainless steel disc stamping and various food-grade steel products.

- 316 and 316L. This stainless steel grade serves as an enhanced version of 300 series stainless steel. This particular grade features molybdenum content that lends additional strength and corrosion resistance, and it’s often used for applications involving marine and pharmaceutical environments, along with food processing.

Metal Stamping from Aranda Tooling, LLC.

If you require high-quality steel stampings for your next project, Aranda Tooling, LLC. can meet your needs. Since 1975, we have become a leading provider of metal stamping services, including progressive die stamping and transfer die stamping. We can produce parts of varying complexity and specifications, working closely with our customers to give them consistently great results.

Browse the rest of our site to learn more about our metal stamping services. You can also request a quote for any of our services or contact us today with any questions, and we’ll put you in touch with a representative.

Request For

Request For

Comments are closed