Aranda Tooling is known as a premier enterprise for metal stamping, metal fabrication, laser cutting, and welding needs. We are proud to have ISO 9001:2015 quality certifications, which gives our customers peace of mind about our capability to provide high-quality products. Our dedication to quality paired with our extensive stamping and fabrication capabilities has earned us repeat customers across many industries, including the medical field.

There are many advantages to using our services to fabricate components for the medical sector. We handle all medical designs with a focus on achieving the tightest possible tolerances and exceeding expectations for quality and functionality. Our ability to complete rapid tool builds enables us to offer quick turnaround times for medical device components and other products under tight deadlines.

Medical Component Manufacturing Services

We offer a variety of services useful for medical component production. Some of these services include:

Medical Metal Stamping

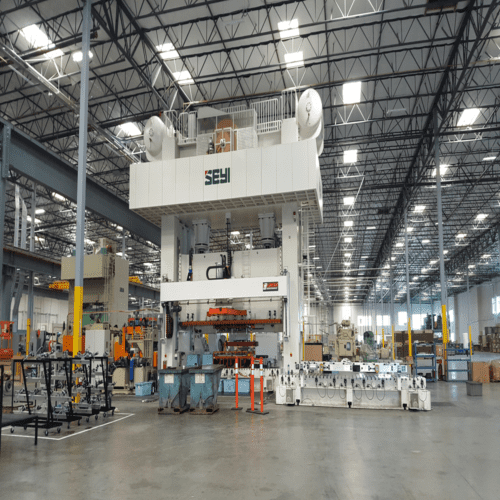

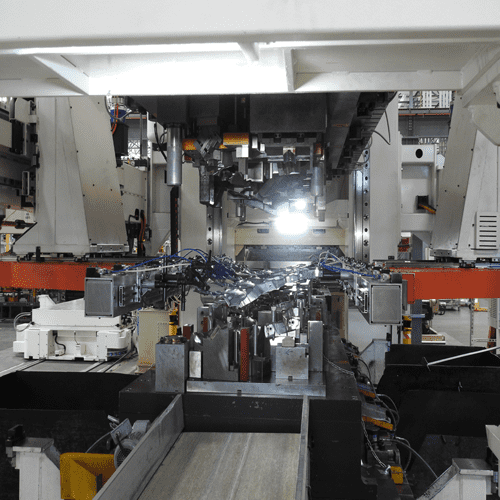

Outfitted with over 50 different punch presses equipped to handle capacities up to 1,300 tons, we consider high-volume precision metal stamping to be one of our core capabilities. We manufacture complex, high-quality stampings and components for a large variety of customers across the medical field. With in-die sensors and automatic robotic transfer equipment, we can meet extremely demanding production volumes in the millions of parts.

We work with part thicknesses ranging from 0.005–0.5 inches and up to 48 inches in width. Our largest press bed can hold tools up to 240 inches by 70 inches. Our maximum mechanical press stroke is 31 inches and our maximum hydraulic press stroke is 18 inches, so we can handle stamping projects of all sizes.

Medical applications often require some of the most rigorous designs and certifications, so we always keep the highest standards throughout the entire medical metal stamping process to ensure the parts we produce will comply with stringent regulations from all relevant government and medical regulatory bodies.

Medical Component Fabrication

At Aranda Tooling, we offer a range of manufacturing capabilities. With a full range of in-house metal fabrication services, we are able to oversee customer projects from initial concept through final assembly.

Equipped with a broad range of advanced fabrication tools, we can meet even the most demanding customer specifications. Some of our primary metal fabrication services include:

- Laser cutting. Our in-house 4000-watt CO2 laser cutting machines allow us to manufacture the most precise medical parts. We can also perform precision laser etching to facilitate labeling and batch tracking.

- Robotic welding. Our robotic weld cells are capable of performing several weld types to ensure repeatable accuracy and precise weld positioning.

- Engineering and design. We can support customer projects from original conception through design, prototyping, and full production.

- Machining. Our team can perform drilling, tapping, and other common machining processes.

- Tooling design and fabrication. We offer full design and fabrication services for stamping dies such as compound, progressive, single hit, and transfer. We also produce other tooling components for assembly, automation fixtures, checking, inspection gauges, welding, and more.

Value-Added Services

At Aranda Tooling, we offer a variety of value-added services to ensure that our customers don’t have to manage multiple vendors. Some of these capabilities include:

- Quality assurance. Our quality assurance capabilities extend beyond standard methods. We can incorporate coordinate measuring machines (CMM), optical inspection systems, ROMER arms, and other advanced inspection methods and techniques upon request.

- Post-processing. We provide post-processing and finishing, such as passivation, through our network of fully vetted, trusted contractors.

Materials for Medical Components

Metal stamping is a versatile process that’s compatible with a variety of metals. When manufacturing medical parts and components, we work with the following materials:

- Aluminum

- Brass

- Bronze

- Copper

- Hastelloy®

- Inconel®

- Low- and high-carbon steel

- Monel®

- Nickel alloys

- Stainless steel

- Titanium

Medical Manufacturing From Aranda Tooling

Aranda Tooling handles every aspect of the manufacturing process to guide projects from conception through final assembly. We are dedicated to providing the superior service and capabilities necessary to meet the precise design and manufacturing needs of the medical industry.

If you would like to learn more about how we can help you with your medical component manufacturing needs, contact us or request a quote today.

Request For

Request For