Metal stamping involves the process of forming metal into desired shapes using techniques such as punching, blanking, bending, coining, and more. Used in industries ranging from automotive to medical, construction, and more, metal stamping offers a cost-effective way of producing parts in large volumes.

Metal stamping involves the process of forming metal into desired shapes using techniques such as punching, blanking, bending, coining, and more. Used in industries ranging from automotive to medical, construction, and more, metal stamping offers a cost-effective way of producing parts in large volumes.

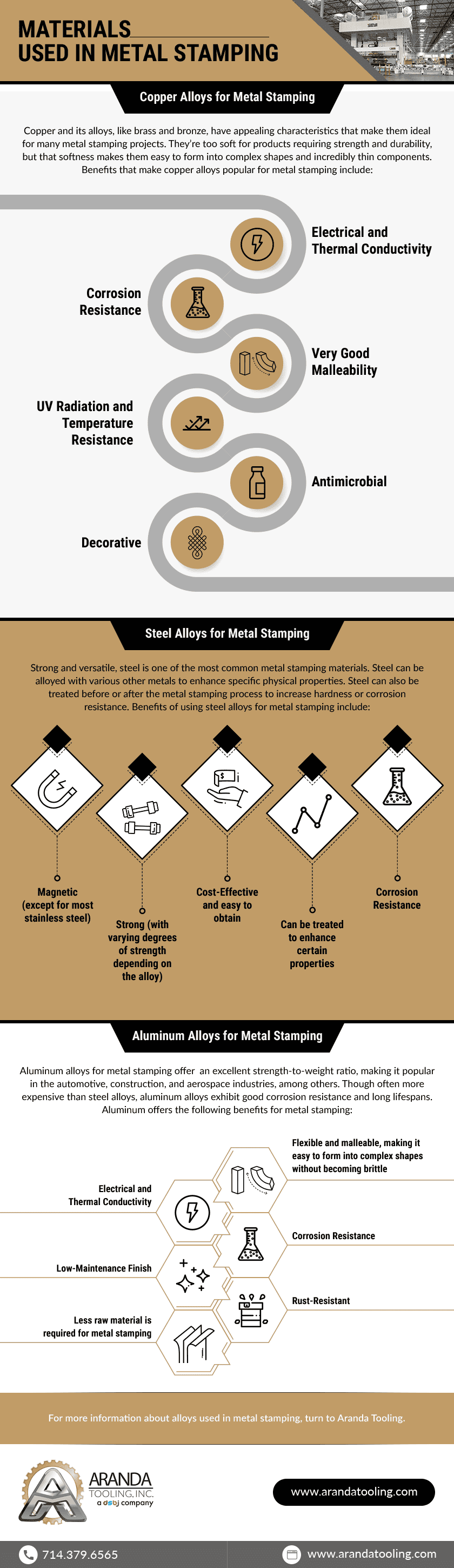

When choosing the best material for metal stamping, it’s important to consider the complexity of the final product and the characteristics you need it to exhibit. Copper, steel, and aluminum alloys are all common material options for metal stamping. Here, we will describe each material and its benefits to help you determine which metal is right for your next metal stamping project.

Choosing the Best Metal for Stamping

The material you choose for your metal stamping project greatly affects the final outcome of the finished product. To ensure that you select the right metal based on your project’s requirements, it’s important to ask yourself the following questions:

- How much does the material cost and will it fit into your project’s budget?

- Will the material be easy to work and shape into the desired product?

- How strong and durable does the material need to be?

- What sort of environmental conditions will the material need to withstand?

- What long-term benefits does the material need to offer?

- How will clients use the finished product?

By answering the above questions, you can narrow down your search for the appropriate metal stamping material. Since there are so many material options, it can be challenging to find the one with the exact characteristics you need. Because of this, it’s always a good idea to work with a trusted metal stamping manufacturer, as they have the necessary knowledge and experience to guide you toward the best material for your needs.

Copper Alloys for Metal Stamping

Copper and its alloys, like brass and bronze, have appealing characteristics that make them ideal for many metal stamping projects. They’re too soft for products requiring strength and durability, but that softness makes them easy to form into complex shapes and incredibly thin components. Benefits that make copper alloys popular for metal stamping include:

- Electrical and thermal conductivity

- Corrosion resistance

- Very good malleability

- UV radiation and temperature resistance

- Antimicrobial

- Decorative

Steel Alloys for Metal Stamping

Strong and versatile, steel is one of the most common metal stamping materials. Steel can be alloyed with various other metals to enhance specific physical properties. Steel can also be treated before or after the metal stamping process to increase hardness or corrosion resistance. Benefits of using steel alloys for metal stamping include:

Strong and versatile, steel is one of the most common metal stamping materials. Steel can be alloyed with various other metals to enhance specific physical properties. Steel can also be treated before or after the metal stamping process to increase hardness or corrosion resistance. Benefits of using steel alloys for metal stamping include:

- Magnetic (except for most stainless steel)

- Strong (with varying degrees of strength depending on the alloy)

- Cost-effective and easy to obtain

- Can be treated to enhance certain properties

- Corrosion resistance

Aluminum Alloys for Metal Stamping

Aluminum alloys for metal stamping offer an excellent strength-to-weight ratio, making it popular in the automotive, and construction, among others. Though often more expensive than steel alloys, aluminum alloys exhibit good corrosion resistance and long lifespans. Aluminum offers the following benefits for metal stamping:

- Flexible and malleable, making it easy to form into complex shapes without becoming brittle

- Electrical and thermal conductivity

- Corrosion resistance

- Low-maintenance finish

- Rust-resistant

- Less raw material is required for metal stamping

Partner with Aranda Tooling for your Metal Stamping Needs

Many materials are suitable for the metal stamping process, so it’s important to consider the needs of your application to narrow down your selection. If you’re not sure which one is right for you, turn to the professionals at Aranda Tooling. With over four decades of experience offering metal stamping and fabrication services, our experienced staff has the knowledge to help you find the best material for your metal stamping project.

For help with your material selection process, or to get started on your next metal stamping project, contact us or request a quote today.

Request For

Request For

Comments are closed