At Aranda Tooling, we are an industry-leading provider of metal stamping solutions. One of our core service offerings is transfer die stamping.

Due to its flexibility and cost-effectiveness, the process is used to create a variety of metal parts and products. Equipped with multiple presses with up to 1320-ton capacities, we use it to produce high volumes of components for domestic and international customers in a wide range of industries. Some of the industries we regularly serve include automotive, electric vehicle, home improvement, manufacturing, medical, and renewable energy.

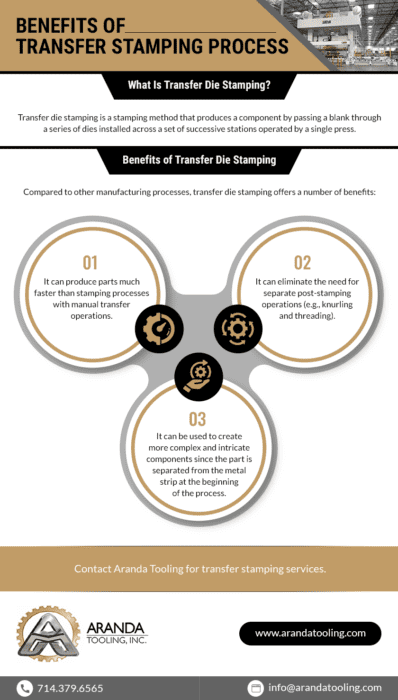

What Is Transfer Die Stamping?

Transfer die stamping is a stamping method that produces a component by passing a blank through a series of dies installed across a set of successive stations operated by a single press. The component blank is first separated from the larger metal strip, allowing it to be freely transferred. Then, it is transferred from one station to the next by a mechanical transport system until it is completely formed, eliminating the need for manual transfer and reducing the risk of misalignment or mishandling. Since transfer operations occur simultaneously—i.e., the workpiece at the first station is transferred to the second station at the same time the workpiece at the second station is transferred to the third station—the production line does not get backed up.

In addition to accommodating different stamping dies, transfer presses can hold tooling for piercing, chamfering, knurling, threading, and other forming processes. This versatility enables manufacturers to combine various secondary operations into the stamping process.

Benefits of Transfer Die Stamping

Compared to other manufacturing processes, transfer die stamping offers a number of benefits. For example:

- It can produce parts much faster than stamping processes with manual transfer operations.

- It can eliminate the need for separate post-stamping operations (e.g., knurling and threading).

- It can be used to create more complex and intricate components since the part is separated from the metal strip at the beginning of the process.

Transfer Die Stamping vs. Progressive Die Stamping

Transfer die stamping is highly similar to progressive die stamping; both processes use multi-station dies to turn a blank into a finished component. The main distinction between them is that transfer die stamping removes the blank from the metal strip at the beginning of the stamping process, while progressive die stamping removes the blank from the metal strip at the end of the stamping process. This process difference makes the two stamping methods suitable for different parts and products; transfer die stamping is better suited for producing larger and more complex components, while progressive die stamping is better suited for producing smaller and simpler components in high volumes.

Transfer Die Stamping Services From Aranda Tooling

Need a partner for your next metal stamping project? The experts at Aranda Tooling have got you covered! Equipped with a broad range of transfer die stamping and progressive die stamping capabilities, we can meet all of your metal stamping needs. To learn more about our metal stamping services, check our metal stamping page or contact us today. To discuss your metal stamping requirements with one of our team members, request a quote.

Request For

Request For