Progressive die stamping offers numerous benefits when compared to other traditional manufacturing methods. Progressive die advantages include:

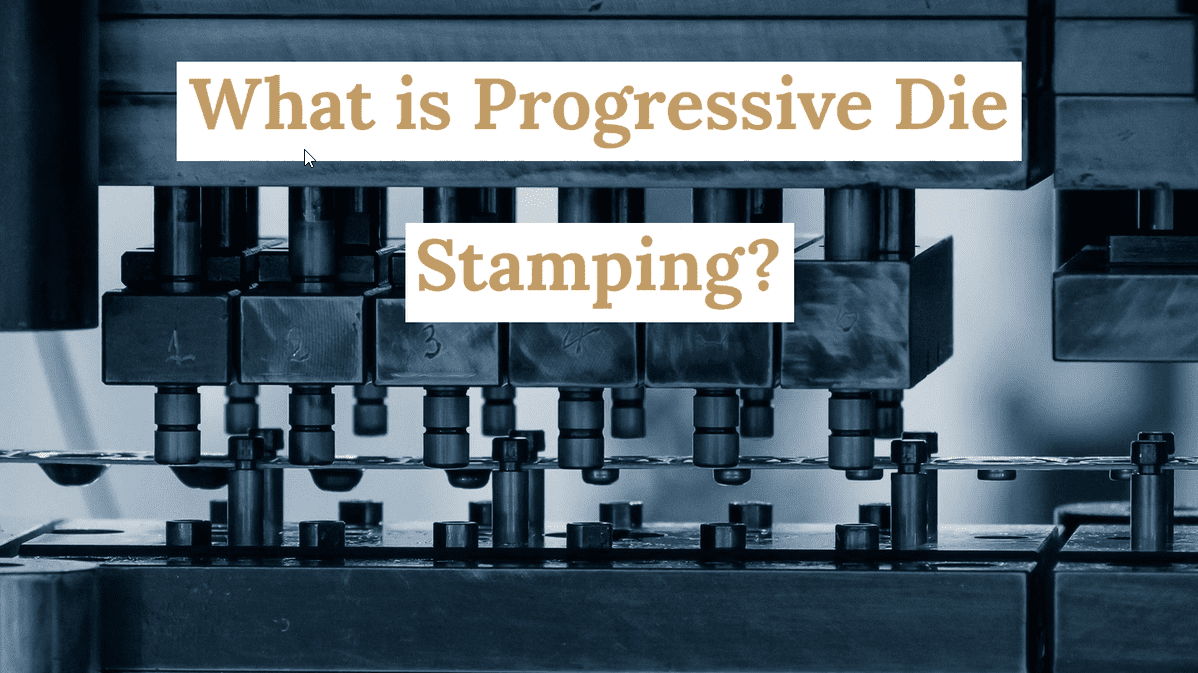

What Is Progressive Die Stamping?

Progressive die stamping, also known as prog die stamping, is a versatile process that allows for efficient, cost-effective manufacturing of numerous parts and products. Capable of producing metal components of varying shapes and sizes, it leads to lower production costs and shorter lead times.

Progressive die stamping, also known as prog die stamping, is a versatile process that allows for efficient, cost-effective manufacturing of numerous parts and products. Capable of producing metal components of varying shapes and sizes, it leads to lower production costs and shorter lead times.

During the progressive die stamping process, a stock strip moves the part through a series of individual work stations, each of which performs its own task on the workpiece, such as bending, punching, and coining. As the part moves through each station, it progressively takes on the desired size and shape. Once completed, the part is cut from the stock strip to reveal the final product.

Advantages of Using Progressive Die Stamping

- Faster Production Speeds. Since parts are continuously fed, the progressive die stamping process can produce more parts quickly. This is especially beneficial for businesses looking to produce at high volumes.

- Less Scrap Material. Using sheet metal to manufacture components creates a smaller waste generation without adding extra metal to the product. The optimized design of the stamping dies also allows for considerably less waste.

- Broader Design Freedom. Progressive die stamping offers broader design freedom. The process can accommodate numerous geometries, ranging from simple to complex.

- Greater Production Capacities. Progressive die stamping allows for increased capacity with longer runs, manufacturing more parts in a shorter period.

- Higher Rates of Repeatability. Progressive stamping equipment uses hard, quality tooling. This means that high-volume production runs are possible without degrading the dies. This results in high-quality, repeatable final products.

- Lower Cost Per Part. Overall production costs are lower when using progressive die stamping due to smaller waste generation, quicker setup, higher repeatability, and faster production speeds. The automated process reduces the risk of workplace injuries and significantly reduces labor costs, needing fewer employees to manufacture components.

- Production of Close Tolerances. The unique process can produce significant volumes of parts while maintaining optimal accuracy and precision.

Progressive Die Stamping Process

Progressive die stamping is a cutting and forming process that uses a die consisting of multiple stamping stations that conduct simultaneous operations on the part as it is carried through via a coiled strip. Specifically, the process follows these steps:

- Tooling creation by toolmakers. Skilled toolmakers must create the tooling, or die set, based on the needs of the specific application. Since this die set contains all the tools necessary to carry out production, the tooling does not need to be changed out between operations.

- Place the die. Once created, the die must be placed into the stamping press. The die opens as the stamping press moves up, and it closes as the stamping press moves down.

- Load the workpiece. Next, the workpiece must be placed in the die. The workpiece moves through the die while it’s open, being incrementally fed into the die with each press stroke.

- Perform operations. The die can change the workpiece in various ways, such as embossing, coining, bending, cutting, and more. Once the die closes, it carries out its operation on the workpiece.

- Part ejection. Once the workpiece moves through each workstation and has taken on its final shape and size, the finished parts are ejected from the die. They can then be cut from the carrier strip.

The progressive die stamping process relies on various equipment to carry out options. This equipment typically includes:

- Stamping presses, such as straight side progressive presses

- Progressive tooling (the die set)

- Coil feed line

Progressive Die Stamping Applications

Progressive die stamping offers a wide range of benefits, including long run lengths, cost-effectiveness, fast production, short setup times, decreased labor costs, minimal scrap, and more. This process’ ability to efficiently produce parts in large volumes makes it a popular choice for several industries and applications, including:

Electronics

Food and beverage

Medical

Appliances

Automotive

Progressive Die Stamping vs Other Stamping Methods

Progressive die stamping is often preferred over other stamping methods due to the many benefits it provides in terms of lead times, production time, and overall cost.

Compound Metal Stamping

During the compound metal stamping process, a metal strip is fed through a compound die, which performs all stamping operations in one stroke. This process is most suitable for projects requiring medium and high-volume production of flat parts. While progressive die stamping offers fast production times regardless of part complexity, compound die stamping can be slower for larger parts with more intricate design elements.

Transfer Die Stamping

One of the main differences between transfer die stamping and progressive die stamping is that the workpiece is separated from the metal strip in the first step. The workpiece is then transferred between several workstations to complete the part. This process is ideal when working with complex designs and larger parts that can’t easily move through die stamping stations.

Traditional Metal Stamping

Traditional metal stamping often utilizes stage tooling for stamping operations. While stage tooling offers lower setup costs, it results in the highest price per piece. With progressive die tooling, you have higher initial costs, but lower costs per piece. In terms of speed and production volume, stage tooling is slower and more ideal for small, low-volume production runs, whereas progressive die stamping is fast and suitable for large production runs.

Progressive Die Stamping Services at Aranda Tooling

As a premier provider of progressive die stamping, Aranda Tooling offers cost-effective solutions for a broad range of applications. Our state-of-the-art facilities and extensive industry experience allow us to manufacture high-quality components that meet precise design implementations.

Specializing in high-volume progressive die stamping runs, we manufacture up to a half million parts daily on a daily basis and can work with the following materials:

- Aluminum

- Titanium

- Brass

- Bronze

- Copper

- Stainless Steel

- Low and High Carbon Steel

- Inconel®

- Nickel Alloys

We can handle virtually any size progressive die stamping project, using an 18″ maximum hydraulic press stroke and 31″ maximum mechanical press stroke. For more information about our progressive die stamping capabilities, contact us today. You can also request a quote to get started.

Request For

Request For