Metal stamping is a popular process in the automotive industry due to its ability to manufacture consistent, complex parts that meet tight tolerances and specifications. At Aranda Tooling, we have upwards of 50 different types of punch presses, making it possible for us to specialize in high volume stamping at capacities of up to 1,300 tons.

We utilize the following types of processes when stamping automotive parts:

- Progressive Die

- Compound Die

- Transfer Die

These capabilities enable our team to manufacture a variety of complex automotive components with precision tolerances.

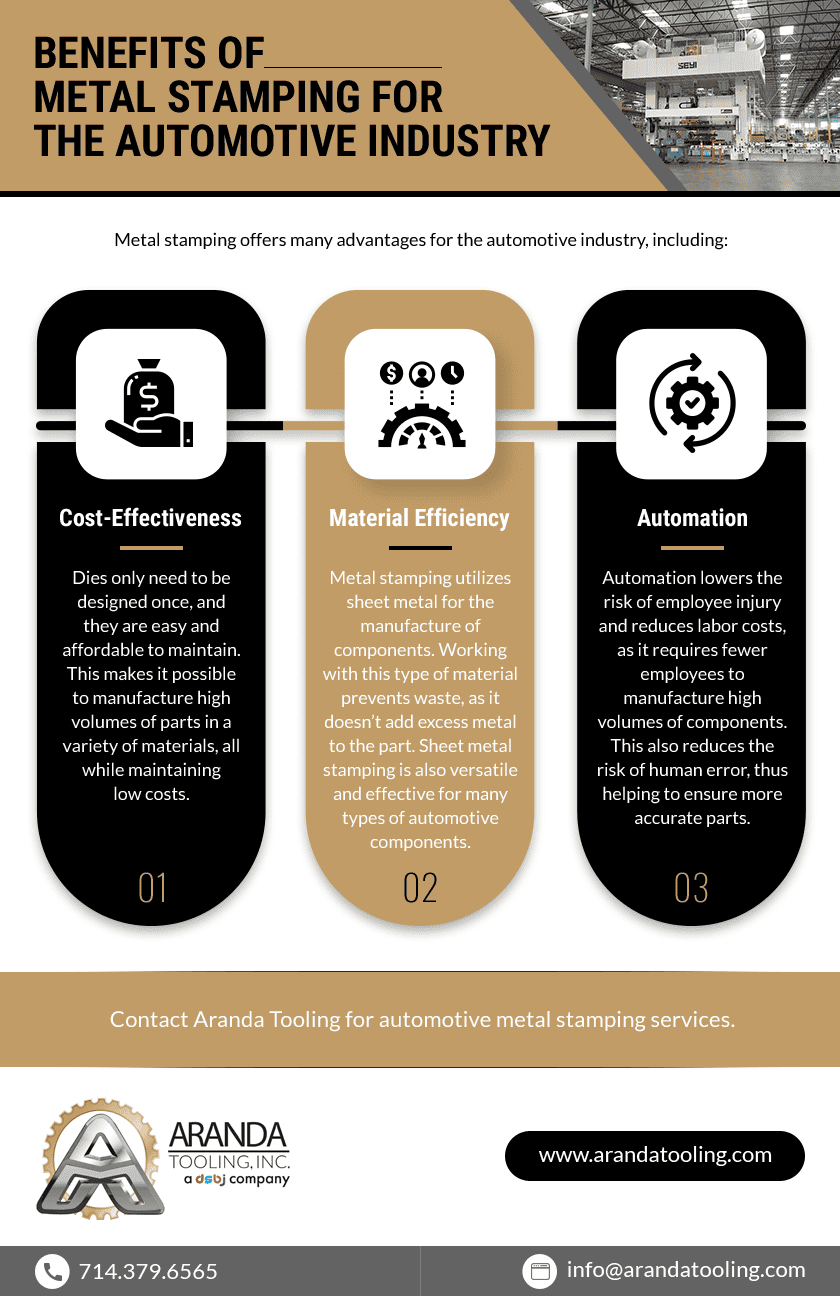

Advantages of Metal Stamping for the Automotive Industry

Metal stamping offers many advantages for the automotive industry, including:

Cost-Effectiveness

Dies only need to be designed once, and they are easy and affordable to maintain. This makes it possible to manufacture high volumes of parts in a variety of materials, all while maintaining low costs.

Material Efficiency

Metal stamping utilizes sheet metal for the manufacture of components. Working with this type of material prevents waste, as it doesn’t add excess metal to the part. Sheet metal stamping is also versatile and effective for many types of automotive components.

Automation

Automation lowers the risk of employee injury and reduces labor costs, as it requires fewer employees to manufacture high volumes of components. This also reduces the risk of human error, thus helping to ensure more accurate parts.

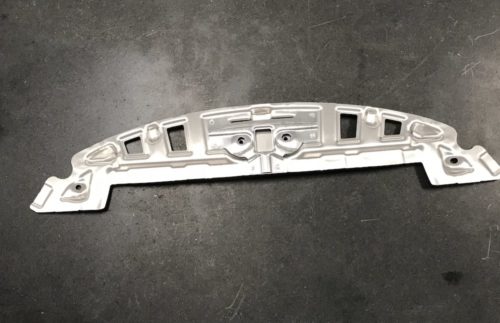

Components Produced by Automotive Metal Stamping

At Aranda Tooling, we work closely with the automotive industry to provide consistently accurate and dependable precision parts ranging in thicknesses from 0.005’’ to 0.5’’ with a maximum part width of up to 48’’. Our maximum press bed is capable of handling tooling of up to 240’’ by 70’’ with a maximum press stroke of 31’’.

These capabilities allow us to produce parts of virtually any size, including:

- Heat Shields

- Cylinder Head Gaskets

- Radiator Frame Assemblies

- Brake Components

- Engine Components

- Seating Components

- BIW Components

- Transmission Components

- Brackets

- Floor Panels

- EV Battery Components

- EV Charging Components

- A-Frames

- Battery Trays

Materials Used in Automotive Metal Stamping

The versatility of automotive metal stamping enables manufacturers to craft parts in a range of materials, each with its own unique properties and benefits. Three of the most common materials in stamping of automotive components are:

- Aluminum. Aluminum is ideal when aesthetics are a concern, as it has an attractive appearance in addition to being conveniently lightweight. This material is perfect for detail work and components that will be visible to consumers. Manufacturers may also choose to strengthen aluminum by creating an aluminum alloy with another material.

- Carbon Steel. This is one of many widely utilized steel options, popular due to its durability.

- Stainless Steel. Thanks to its high chromium makeup, stainless steel is highly resistant to corrosion and rust. This material also has the added benefit of being aesthetically appealing.

In addition to aluminum, carbon steel, and stainless steel, we utilize the following materials in our automotive metal stamping processes:

- Titanium

- Brass

- Bronze

- Copper

- Inconel

- Nickel Alloys

Automotive Metal Stamping Services from Aranda Tooling

Founded in 1975, Aranda Tooling has become one of the leading metal stamping, laser cutting, and metal fabrication companies in the industry. Our team of experts is well-versed in producing precision parts that meet stringent specifications, and we work closely with our customers to determine the ideal material and die stamping process for their project’s unique needs. We are dedicated to meeting and exceeding the needs of each customer as we continue to serve the automotive industry. To learn more about our metal stamping services, or to work with us on your next project, contact us or request a quote today.

Request For

Request For