Metal stamping is a crucial part of modern industry for producing precise components for various sectors. The process uses a press to create specific shapes out of rolled or sheet metal. Several metal forming techniques can be used to produce stamped metal parts, including bending, piercing, punching, and blanking. Discover Aranda Tooling’s metal stamping services, capabilities, certifications, and more.

Our Services

We perform three different types of metal stamping processes: progressive die, transfer die, and automotive metal stamping.

Progressive Die Stamping

Progressive die stamping involves processing a strip of metal in a series of

stages that perform various individual operations. As the strip moves from one station to another, it is stamped according to its intended design until complete. The last step is to separate the individual metal parts from the strip. Progressive die stamping is ideal for quickly, efficiently, and accurately producing metal parts with different features, such as washers, clips, and brackets.

Transfer Die Stamping

Transfer die stamping involves a mechanical transport system that moves parts from station to station. This method first removes individual metal parts from a larger strip so that more detailed operations can be performed on them. It is commonly used to produce shells, frames, tubing, and structural components.

Automotive Metal Stamping

Automotive metal stamping facilitates the production of large volumes of identical, complex components that meet strict specifications. It is a popular method for electric car manufacturing.

Benefits of Using Aranda Tooling’s Metal Stamping Services

Working with Aranda Tooling for your metal stamping projects comes with numerous advantages, including:

- Cost-effectiveness: Aranda Tooling’s advanced equipment and skilled technicians can produce high volumes of stamped metal parts with less waste, ensuring cost-effectiveness.

- Precision: Aranda Tooling uses specialized metal stamping tools that can achieve tight tolerances, guaranteeing precise parts every time.

- Quick turnaround time: At Aranda Tooling, we use high-speed metal stamping machinery and efficient production processes to meet your deadlines.

Our Capabilities

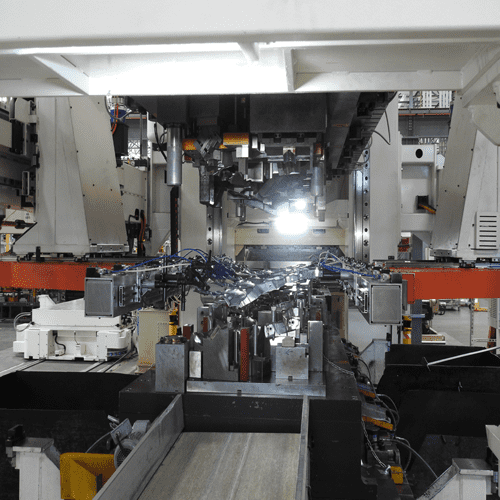

Aranda Tooling’s cutting-edge facility specializes in high-volume metal stamping, using a variety of stamping techniques and metal materials—including aluminum, carbon steel, and stainless steel. We have more than 50 punch press machines capable of handling capacities of up to 1,300 tons.

We have also invested in different metal stamping tools to facilitate the production of parts with a wide range of sizes and complexities. Our light to heavy gauge stamping capabilities allow us to manufacture parts with thicknesses ranging between 0.005” and 0.5” and a maximum part width of up to 48”. We can achieve tolerances of ±0.005”, with tighter tolerances possible upon request.

Our maximum press bed can accommodate tooling up to 240” by 70”. To help fulfill projects of nearly any size, we use a maximum mechanical press stroke of 31” and a maximum hydraulic press stroke of 18”.

In addition, Aranda Tooling offers in-house die and tooling design and manufacturing to streamline the production process. Our custom metal stamping services use fully automated robotic transfer mechanisms and in-die sensors, which allow us to fulfill even the most demanding production volumes. On any given day, our facility can fabricate up to half a million parts.

To give you a better idea of our capabilities, here are some of our previously stamped parts and the processes we used:

- Radiator frame assembly (metal stamping)

- Cylinder head gasket (progressive die stamping and assembly)

- Tin-plated paint pan for the commercial and painting industry (transfer die stamping)

- Zinc-plated diaphragm cover for commercial and safety-specific industries (progressive die stamping)

- Heat shield (progressive die stamping)

Quality Control

Aranda Tooling has more than four decades of industry experience. We recognize the importance of quality in the manufacturing industry, so we are proud to be an ISO 9001:2015 certified and APQP certified company. Our team produces more than 1,000,000 precision components per week to satisfy our large, growing customer base around the world.

Metal Stamping Services From Aranda Tooling

Stamping is a crucial part of manufacturing and part production. If you have an application that requires metal stamping services, you need to work with a company that ensures accuracy, precision, and speed for every project.

Since 1975, Aranda Tooling has been an industry leader in metal stamping. Our professionals deliver parts with exacting manufacturing specifications, tolerances, and design elements. Contact us today for all metal stamping needs you may have.

Request For

Request For